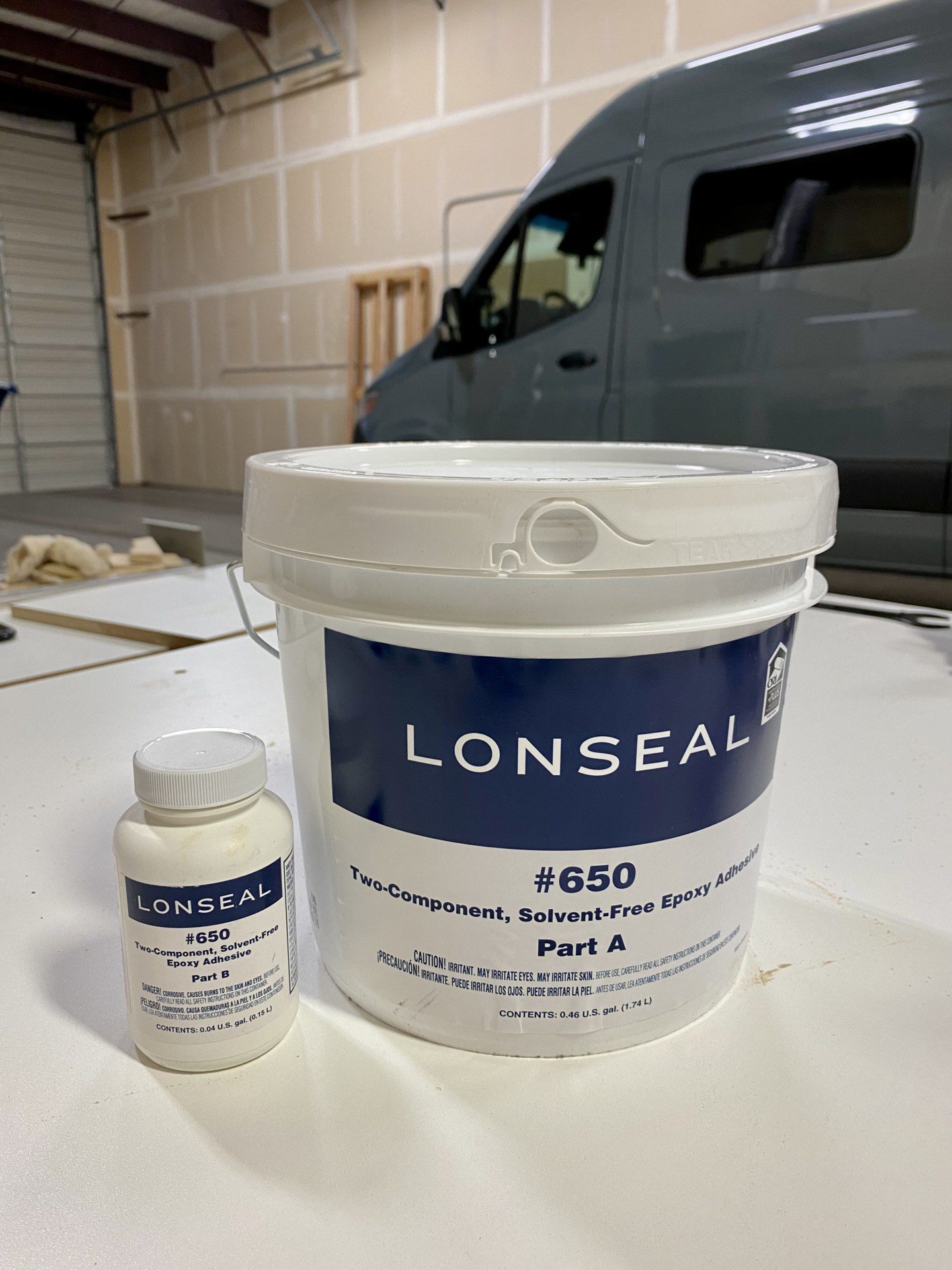

Lonseal #650 Solvent-Free Epoxy Flooring Adhesive is formulated for the high-performance installation of Lonseal flooring on floors in camper vans, tiny homes, and yachts.

Lonseal #650 Solvent-Free Epoxy Flooring Adhesive is an Official Nomadic Supply Company Product that we use to build our luxury Mercedes Sprinter camper vans.

Lonseal #650 Two-Component Solvent-Free Epoxy Flooring Adhesive Features:

- Approximate coverage per half gallon: 85-100 square feet (We recommend a half gallon for a 144″ Wheelbase Mercedes Sprinter van)

- Approximate coverage per gallon: 170-225 square feet (We recommend a gallon for a 170″ Wheelbase Mercedes Sprinter van)

- Wet set adhesive

- CRI Green Label Plus Certified #GLP59909

- Open Time (the time between the two-part epoxy being mixed until placing the flooring material into the adhesive) is up to 15 minutes

- Working Time (the time for the adhesive to accept the flooring material after being applied to the substrate) is up to 15 minutes

- Applications:

- Properly prepared, non-porous substrates and existing vinyl floors

- Locations with temperature extremes, such as saunas, cold-storage, or walk-in freezers

- Areas where flooding is possible, including around drains, shower areas, public bathrooms, pool/whirlpool aprons, or laundry rooms

- Areas expecting heavy point loading or heavy/dynamic rolling loads, like hospital beds

- Can be used on properly prepared, non-porous substrates and existing vinyl floors

Lonseal #650 Two-Component Solvent-Free Epoxy Flooring Adhesive Advantages:

Wet set adhesive

CRI Green Label Plus Certified #GLP59909

For locations with temperature extremes, such as saunas, cold-storage, or walk-in freezers

For areas where flooding is possible, including near drains, showers, bathrooms, pools, or laundry rooms

For areas expecting heavy point loading or heavy/dynamic rolling loads, like hospital beds

Can be used on properly prepared, non-porous substrates and existing vinyl floors.

Lonseal #650 Two-Component Solvent-Free Epoxy Flooring Adhesive Specifications:

- Color: Beige

- Solids: 100%

- VOC: 10 g/L (mixture)

- Part A: 916 U.S. gal.

- Part B: .083 U.S. gal.

- Part A bucket size is approximately 1.5 U.S. gallons

- When Part A and B are combined the bucket will appear to be approximately 2/3 full

- Wt. /Gal.: 11.6 lbs./gal.

- Shelf Life: 1 Year, When stored unopened

- Storage Conditions: 70 ° F 85 and (21.1 ° C 29.4 &)

- Keep dry and out of direct sunlight in a well-ventilated area.

- Application Conditions: 70 and 85 and (21.1 and 29.4 &)

- Container Size: 1 gal.

- Approx. Coverage Area: 170-225 Square Feet

- Concrete Requirements: 5 lbs./1,000 ft2/24 h max. MVER; 75% max. RH; 9 pH max.

- Lonseal #650 Solvent-Free Epoxy Flooring Adhesive Half Gallon Part Number: ZAD650.5 + ZAD6501

- Lonseal #650 Solvent-Free Epoxy Flooring Adhesive 1 Gallon Part Number: ZAD6501

Lonseal #650 Solvent-Free Epoxy Flooring Adhesive Application Information:

- Adhesive must be applied by a trowel with 1/16″ x 1/32″ x 1/32″ U-Notches (Model ZZ800 Trowel Sold Separately). These specs are specifically recommended by the adhesive MFG. If applied incorrectly the flooring will not lay properly.

- Approx. Spread rate: 170 – 225 sq. ft./gal. *

- Open time: Up to 15 minutes

- Working time: Up to 15 minutes

Notes: Trowel sizes listed are by width/depth/space. All information provided above will vary depending on the job site conditions, including temperature, humidity, substrate porosity, and applicator.

*Actual job site spread rate will vary depending on the substrate conditions.

OPEN TIME: Waiting time is required before placing the flooring material into the adhesive.

WORKING TIME: Amount of time for the adhesive to accept the flooring material after being applied to the substrate.

Attention: Always refer to the Technical Manual for Interior Flooring Products and/or Technical Manual for Exterior Products for complete installation information prior to using this product. Lonseal reserves the right to change our products’ design, material, and/or to improve products or processes at any time without notice. Installation procedures and use of Lonseal adhesives must be in strict accordance with Lonseal’s technical documents for warranty terms to be valid. Please review the website for the most current technical information.

- Application:1. Pour all of Part B into Part A. Allow enough time for the material to flow completely out of the container. Parts A and B are packaged to exact quantity ratios for proper curing, so always mix complete units. Do not add other materials to the mixture. Use a mechanical mixer (slow speed, less than 375 RPM), and mix thoroughly to achieve a smooth, homogeneous mix. Avoid air entrapment and prolonged mixing; both will shorten the pot life of this product. Inadequate mixing will cause bond failure. Pot life at 73 °F (23.8 °C) is approximately 30 minutes. Do not mix more adhesive than can be used in a 30-minute period.

- Pour the adhesive onto the substrate immediately after mixing, and spread using a 1/16” x 1/32” x 1/32” U-notch trowel. Do not allow it to sit in the container, and do not back-roll the adhesive.

- Lay the flooring material into the adhesive after it has been spread, taking care not to trap any air bubbles, and roll in both directions with a minimum 75 lb., three-section roller, checking for full adhesive transfer from the substrate to the back of the material. Roll again 2 to 3 hours later.

- Allow no foot traffic for a period of 24 hours after the installation, and allow 72 hours for the adhesive to fully cure, before setting heavy furnishings or allowing heavy traffic.

Clean Up: Promptly clean all hands and tools with ethyl alcohol after mixing. Use ethyl alcohol applied to a clean, dry cloth to wipe up any adhesive residue from the surface of the flooring while still wet. Do not apply ethyl alcohol directly to the material. Always use caution when working with ethyl alcohol. Take care when removing the cured adhesive from the surface of the sheet vinyl. Using a clean, damp cloth, gently remove the adhesive by wiping it from the surface. Due to the embossing of some products, it may be impossible to remove cured adhesive without permanent damage to the surface. Because of this, always attempt to remove the adhesive while it is still wet.

Limitations: Protect from freezing. Use only when the substrate temperature is 65 °F – 85 °F (18.3 °C – 29.4 °C).

Physical Properties:

Color: Beige

Solids: 100%

VOC: 10 g/L (mixture)

Wt. /Gal.: 11.6 lbs./gal.

Shelf Life: 1year, when stored unopened

Storage Conditions: 65 °F – 85 °F (18.3 °C – 29.4 °C); keep dry and out of direct sunlight in a well-ventilated area.

Application Conditions: 65 °F – 85 °F (18.3 °C – 29.4 °C)

Container Size: 1 gal.

Concrete Requirements: 5 lbs./1,000 ft2/24 h max. MVER; 75% max. RH; 9 pH max.

Approximate Spread Rate:

Note: The trowel size listed is by width/depth/space. All information provided in the adjacent table will vary depending on job site conditions, including temperature, humidity, and substrate conditions.

*APPROXIMATE SPREAD RATE: Actual job site spread rate will vary depending on the substrate conditions.

†OPEN TIME: Waiting time is required before placing the flooring material into the adhesive.

‡WORKING TIME: Amount of time for the adhesive to accept the flooring material after being applied

to the substrate.

Up to 15 minutes†

Up to 15 minutes‡

U-notch Trowel:

1/16″ x 1/32″ x 1/32″

170 – 225 sq. ft./gal.*

Lonseal #650 Solvent-Free Epoxy Flooring Adhesive Documents:

Lonseal #650 Solvent-Free Epoxy Flooring Adhesive Technical Data Sheet (PDF)